|

|

|

|

Since 1956・・ NO.1 in The World Fuji Preheater |

|

|

|

| Function of High Frequency Preheating |

| High Frequency (H.F.) Preheating of Thermo-set plastic

by taking advantage of the H.F. Dielectric Heating principle makes more

efficient and trouble-free such Molding process as for compression

transfer and pultruction molding.

H.F. Preheating of resin before molding contributed to reduction of the cycle time to 1/2-1/5, decrease of insufficient filling of the resin and air-entrapping, resultantly increase of the yield, and improvement to insulation endurance and other physical strength of the product. The H.F. Preheating process is widely applied for Thermo-set plastic molding such as for electric components, mechanical parts, melamine tableware, and packaging of IC, transistors and other micro-electronic components, In the FRP pultruction and SMC/BMC molding process, H.F. Pre-heaters are also developingly used. |

| Principle of H.F. Dielectric Heating |

| Fundamentally different from External Heating by means

of thermal conduction, radiation, and convection, the H.F Dielectric

Heating is called Internal Heating, i.e. the materia1 generates heat by

itself in the result of molecular friction? Electrical insulation material such as plastic and wood has generally a poor thermal conduction. However, when H.F. power with 3-100 MHz is applied to such material, it forces molecular (dipole) to move as much as, for instance 73*1,000,000 times at 73MHz, resulting in generation of molecular friction and further in rapid generation of internal heat. This feature the H.F. Dielectric Heating process and makes it incomparable with other methods. |

| Merits of HF Heating |

| Reduction of the molding cycle time by l/2 - 1/5. | |

| Improvement of fluidity, resulting in sufficient filling resin into die without voids and air-entrapping. | |

| Virtually no need for de-gassing step in the mold cycle . | |

| Improvement in electrical insulation property of the product and restraint of formalin efflux from mold melamine product. | |

| Reduction of worn-out speed of both the die and the plunger. | |

| Reduction of the required molding pressure, or possible resin filling of a lager volume with the same pressure. | |

| Less risks of damaging wires in the IC and Semiconductor packaging operation. |

| FUJI HF Pre-Heaters |

| Ranked No.1 in the world. | |

| Minimized radio field leakage, meeting with world wide regulations. | |

| Well designed for safe and easy operation and maintenance. | |

| High heating efficiency thanks to high oscillation efficiency and low circuit loss. | |

| Easy access operation panel and automatic hood. | |

| Substantial know-how and years of experiences for more uniform and rapid preheating with a higher yield. | |

| After-sales servicing organizations world wide. |

| Principle Features of Standard Models |

|

|

|

| More Efficient and Uniform Heating |

|

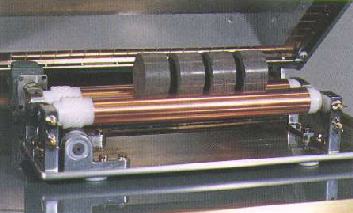

Roller Electrode type |

|

|

Flat Electrode type |

|

| Custom-made Electrodes |

|---|

| Temperature distribution control in length | Temperature distribution control in diameter: narrow pitch |

|---|---|

|

|

|

| Custom made electrode mounted on flat electrode | Temperature distribution control in diameter: wide pitch |

|

|

|

| Infra-Red Temperature Control System for more accurate control |

| Infrared (IR) Temperature control system, a built-in-option on FUJI Pre-heater, shuts HF Power off at the preset temperature by IR Sensor detecting the measured radiation value of resin to have reached the preset value. Resin temperature is shown on the display and temperature setting is also available on the display. |

|

|

| Features and Specification of FTH-1000 system |

|

| Difference between IR Temperature Control System and conventional Timer Control System in function against input power variation. |

|

| Specification of Standard FDP-series |

| FLAT ELECTRODE TYPE |

| FDP-220M | FDP-320M | FDP-520M | FDP-720M | FDP-1020M | |

| HF Output (kW) | 2 | 3 | 5 | 7 | 10 |

| Frequency (MHz) | 62 | 62 | 62 | 62 | 27.12 |

| Line Voltage | 3-phase 200V | 3-phase 200V | 3-phase 200V | 3-phase 200V | 3-phase 200V |

| Line Input (kVA) | 4 | 6.7 | 11 | 14 | 20 |

| Heating Capability | 90deg. 90sec. | 90deg. 90sec. | 90deg. 90sec. | 90deg. 90sec. | 90deg. 90sec. |

| Phenol Resin | 600g | 1000g | 1700g | 2200g | 3400g |

| Melamine Resin | 420g | 700g | 1200g | 1500g | 2400g |

| Electrode Size (mm) | 200x200 | 230x270 | 300x350 | 300x-350 | 420x480 |

| Electrode Distance (mm) | 20~70 | 25~80 | 30~80 | 30~80 | 35~80 |

| Hood Drive | Motor Driven | Motor Driven | Motor Driven | Motor Driven | Motor Driven |

| Dimensions (mm) W x D x H |

418x680 x1260 |

518x790 x1315 |

618x880 x1370 |

618x880 x1370 |

858x1135 x1545 |

| Gross Weight (kg) | 150 | 190 | 300 | 300 | 550 |

| ROLLER ELECTRODE TYPE |

| FDP-223M | FDP-223MX | FDP-323M | FDP-523M | FDP-723M | FDP-1023M | |

| HF Output (kW) | 2 | 3 | 5 | 7 | 10 | |

| Frequency (MHz) | 75 | 75 | 75 | 75 | 75 | 40.68 |

| Line Voltage | 3-phase 200V | 3-phase 200V | 3-phase 200V | 3-phase 200V | 3-phase 200V | 3-phase 200V |

| Line Input (kVA) | 4 | 4 | 6.7 | 11 | 14 | 20 |

| Electrode Size (mm) | 100 | 120 | 150 | 200 | 200 | 200 |

| Tablet Diameter (mm) | 25~40 | 40~60 | 40~60 | 40~70 | 40~70 | 40~70 |

| Hood Drive | Motor Driven | Motor Driven | Motor Driven | Motor Driven | Motor Driven | Motor Driven |

|

Dimensions (mm) |

418x680 x1260 |

518x790 x1315 |

518x790 x1315 |

618x880 x1370 |

618x880 x1370 |

858x1135 x1545 |

| Gross Weight (kg) | 150 | 160 | 190 | 300 | 300 | 550 |

| Custom Made / Special Models |

| Contact us..... |

© Fuji Electronic Ind. Co. All rights reserved.