The use of SPS processing makes practical the compacting rapidly solidified powders

(average grain diameter of about 120mm) of high-Silicon/Aluminum alloys (12% or higher Si content) having

a nano-crystalline structure, which have been prepared by water atomization, into cylindrical

pellets with a diameter of 60mm and a thickness of 40mm. The process is performed rapidly and permits the

retention of nanometric sized crystals. A sintered compact with a relative density of almost 100% has been

obtained under atmospheric SPS sintering conditions including SPS temperatures of 723K to 773K, pressures

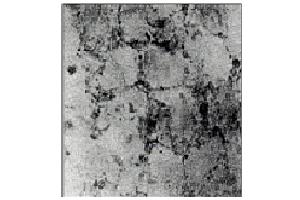

of 100 to 150MPa and a temperature rise and holding time of about 20 minutes. The observation of the

developed nanostructures by means of TEM micrography has shown that the grain diameter of the sintered

compact was between 600 and 800 nm. When this bulk sintered compact was formed into 3D shapes using a

high-speed forging press, it demonstrated that satisfactory forming was possible for lengths of about

75mm in approximately 15 to 20 seconds per stroke with a strain rate speed of 10-2S-1 or higher.

These results indicate that SPS allows the phenomenon of superplasticity to be developed in the material,

improving the ductility of the sintered compact thus investing it with an important new property.

The sintered compact has a tensile strength at normal temperatures of about 350 MPa, approximately 1.5

times stronger than a conventionally forged compact. This new Al-High-Si alloy material with its nanometric

structure is expected to find wide applications in the fabrication of components for electrical appliances

for the home and automobiles.

■Source: Association for the R&D Institute of Metals and Composites for

Future Industries (RIMCOF), Kubota, Ltd., Proceedings of the Public Forum on Development of Component

Fabrication Technology Using High-Speed Superplasticity, 1999.

MATERIALS FOR ELECTRONIC APPLICATIONS

SPS Research on electronic materials has included studies of SiGe,

PbTe, BiTe, FeSi2, CoSb3 and MnSi2 for thermoelectric semiconductor applications,

superconducting, magnetic, target and dielectric materials, hydrogen-occlusion and shape memory alloys, solid cell

materials, piezo-electric/pyro-electric devices and optical functional materials.

- Improvement of the Superplasticity and Specific Strength of Al-Hi-Si Alloy Materials -

|

|---|